Iranian pistachios health and safety

Introduction

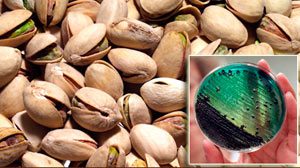

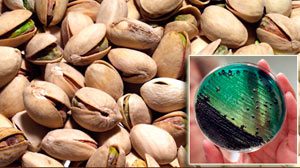

Iranian pistachios are globally exported in large quantities. Iran, one of the leading exporters, adheres to stringent pistachios health and safety standards to prevent and manage potential contamination. This article will discuss the primary sources of contamination in Iranian pistachios and the methods used to control them.

Health safety issues of Iranian pistachios

When addressing the health safety issues of Iranian pistachios, it is crucial to focus on three main topics: Aflatoxin contamination, pesticide residue, and microbiological contamination. This article will provide detailed explanations of each issue, specifically concerning Iranian pistachios.

Aflatoxin

Aflatoxin as a harmful substance is generally produced by certain molds (Aspergillus flavus and Aspergillus parasiticus). Pistachios in particular and other tree nuts, ground nuts, dried fruits, spices, and cereals are highly in danger of aflatoxin contamination. Feed supplies and food aflatoxin contamination may cause serious consequences for animal and human health.

Three important factors in aflatoxin contamination of pistachio trees are time, heat, and moisture. Due to the importance of aflatoxin-free pistachio nuts for export, some techniques are used by Iranian farmers and exporters to prevent aflatoxin contamination in the products.

Pistachio aflatoxin mostly occurs in farms, then by following good manufacturing and processing practices, there is little chance of adding aflatoxin during pistachio processing, warehousing, or export trade shipment.

The primary source of pistachio aflatoxin contamination occurs on the farms. Iranian pistachio farming has significantly improved in recent years to address this issue. The adoption of drip irrigation has been instrumental in preventing aflatoxin contamination. It helps maintain adequate moisture levels for the trees, reducing the risk of aflatoxin production during periods of water stress. Growing drip irrigation in Iranian pistachio farming has diminished the aflatoxin issue a lot.

Farmers have also adopted the technique of accelerating crop harvesting and processing to reduce moisture content significantly and prevent further aflatoxin contamination, as mentioned earlier since time is a critical factor in aflatoxin prevention.

Temperature effect on controlling aflatoxin

Pistachios can be stored at normal temperatures if the moisture content of the nuts is below 6%, preventing aflatoxin contamination. It takes less than 24 hours from harvesting to drying. Once dried, the nuts should be placed in bags and stored in warehouses to maintain stable temperature and moisture levels. Sometimes the moisture content is between %10 and %5 in the final phase of drying.

Pistachios can be stored for over 24 hours safely without aflatoxin issues. It’s important to note that aflatoxin contamination varies, affecting only a few nuts in a consignment. Recent advancements have enabled processors to mitigate aflatoxin risk in imported consignments. However, complete assurance of aflatoxin-free pistachios remains a statistical challenge.

Pesticide

The pesticide issue presents a new challenge to the food industry, and Iranian pistachios have been addressing this challenge for about 10 years. Farmers in Iran have actively worked to minimize pesticide residue in their products. Their efforts aim not only to enhance profitability but also to respond to the increasing demand for pesticide-free pistachios, which have become more lucrative in recent years.

Pesticide residue testing is expensive and challenging in local labs, prompting Iranian farmers and exporters to often send samples to Europe for analysis. The major pest of Iranian pistachio farms is called Psylla. Iranian farmers were in trouble to control this pest in 7 or 8 years ago. At that time, they were using a chemical pesticide that was effective in controlling pests for 2 or 3 years.

After that it lost its effect and Iranian farmers figured out how to use sulfur to control their farms from pest residue. This method is very effective and eliminates pest residue problems in most of Iranian pistachios. Unlike aflatoxin, pesticide residue contamination in pistachio is homogenous.

Microbiological contamination

Microbiological contamination can also affect the pistachio orchards by bird infestation. These defects are visible, so pistachio nuts with bird defects are sorted out during dry processing.

Iranian pistachios are usually roasted at very high temperatures for a long time. This process removes any microbiological contamination. In case of raw pistachio of green peeled pistachio kernels, as they are raw, the processors should follow very strong standards to prevent any microbiological contamination.

Ensuring health in Pistachio Management

Due to the importance of Iranian pistachio health and the huge amount of Iranian pistachios exported annually, we tried to cover the main health and safety issues of Iranian pistachios. Three main topics were mentioned above: aflatoxin contamination, pesticide residue, and microbiological contamination. We covered all useful techniques and methods to control and prevent such contaminations in Iranian pistachios.